Engine Driven Davey Firefighter® Pumps

- Home /

- Brands /

- Davey Water /

- Engine Driven Davey Firefighter® Pumps

Engine Driven Davey Firefighter® Pumps

Are you bushfire ready?

Davey Firefighter® – more than the name suggests.

The Davey Firefighter is best known for its reliability in fire protection and prevention, but did you know it is one of the highest selling pumps for water transfer too?

Not only can Davey single and twin stage Firefighters be used for fire prevention and protection, their ability to move large volumes of water is second to none. They are used for water transfer just as much as they are used in a bushfire situation. They are built tough, built in Australia, and can handle tough Aussie conditions.

Davey Firefighter – Get ready with the BEST

A fire plan is the first step to ensuring you are on the way to being bushfire ready. The second step is to ensure you, your equipment and your home are protected. You need an engine powered pump for both asset protection as well as post fire management of burning fences, surrounding vegetation and other structures including buildings.

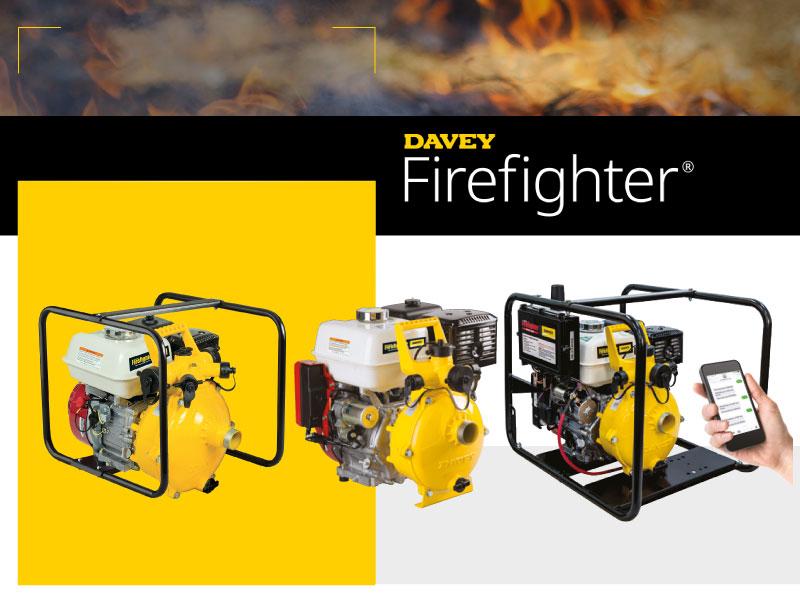

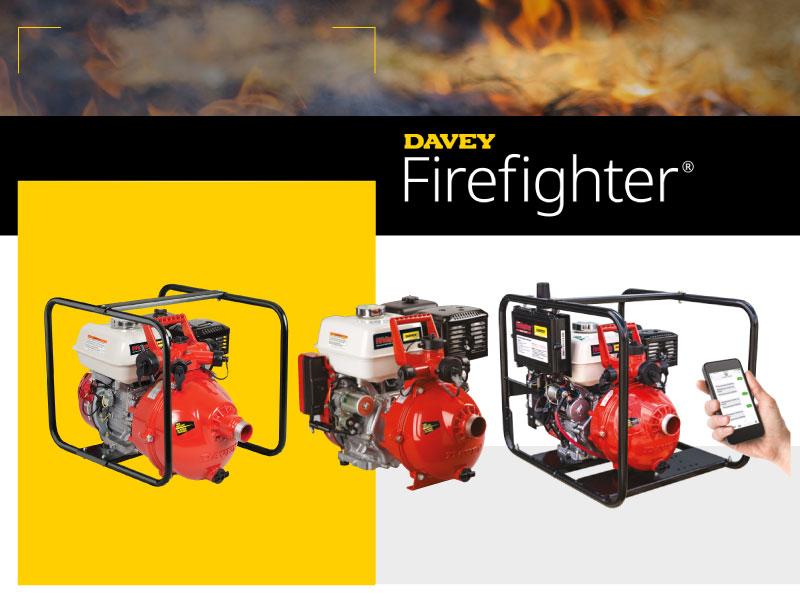

Single Stage, Twin Stage, Petrol or Diesel - the choice is yours

With single and twin stage options, and your choice of higher flow or higher pressure, the class leading performance Davey Firefighter is number 1 in Australia, and sold worldwide. Davey Firefighter® pumps are available with a choice of Honda engines. Larger Honda petrol engine models and Yanmar diesel powered models are also available.

Advice. Products. Solutions. Locally source and buy Engine Driven Davey Firefighter® Pumps from Irrigear Lowood your local Irrigear® Independent Experts — the leaders in pumping, irrigation, filtration, water and fluid management.

- Firefighting

- Post fire management

- Tanker to tanker water transfer

- General water transfer

- High head general water transfer

- Sheep jetting

- Irrigation

- Boom spraying

Davey Firefighter® Petrol Engine Pumps – Models

With single and twin variations, and your choice of higher flow or higher pressure, the class leading performance Davey Firefighter is number 1 in Australia, Provides high head performance at 3600rpm whilst still being able to operate across the full pump curve without overloading the engine. Models in the range of the petrol engine driven Davey Firefighter include:

- 5150HD - entry level, single stage, 163cc Honda GP160 engine with flow rates up to 415 lpm

- 5155H - single stage, 163cc Honda GX160 engine, flow rate up to 415 lpm

- 5155HV - single stage, 163cc Honda GX160 engine, flow rates up to 415 lpm, with Viton elastomers

- 5155H3 - single stage, 163cc Honda GX160 engine, flow rates up to 415 lpm, and 3-way outlet

- 5113HE - single stage, 389cc Honda GX390E electric start engine, flow rates up to 880 lpm, and 3-way outlet

- 5165H - single stage, 196cc Honda GX200 engine, flow rates up to 500 lpm

- 5190HE - single stage, 270cc Honda GX270E electric start engine, flow rates up to 800 lpm

- 5165HE - single stage, 196cc Honda GX200 electric start engine, flow rates up to 500 lpm

- 5165HQ - single stage, 196cc Honda GX200 engine, flow rates up to 500 lpm, and 3-way outlet

- 5213HE - twin stage, 389cc Honda GX390E electric start engine, flow rates up to 660 lpm, and 3-way outlet

- 5255H - twin stage, 163cc Honda GX160 engine, flow rates up to 375 lpm

- 5265H - twin stage, 196cc Honda GX200 engine, flow rates up to 400 lpm

- 5265H23W - twin stage, 196cc Honda GX200 engine, flow rates up to 400 lpm, and 3-way outlet

- 5265H3 - twin stage, 196cc Honda GX200 engine, flow rates up to 400 lpm, and 2" 3-way outlet

- 5265HE - twin stage, 196cc Honda GX200 electric start engine, flow rates up to 400 lpm

- 5265HV - twin stage, 196cc Honda GX200 engine, flow rates up to 400 lpm, with Viton elastomers

- 5290HE - twin stage, 270cc Honda GX270 electric start engine, flow rates up to 590 lpm

Davey Firefighter® Diesel Engine Pumps – Models

Help protect your property and your family with a Davey Firefighter. Davey's high quality, reliable fire pumps are in demand all over the world. Don't wait for an emergency, get prepared with a Firefighter right now. Provides high head performance at 3600rpm whilst still being able to operate across the full pump curve without overloading the engine. Models in the range of the diesel engine driven Davey Firefighter include:

- 5170YE

- 5210YE/HP

- 5270YE

Rugged, economical single stage engine driven pumps. Ideal for firefighting, tanker to tanker water transfer, high head general water transfer, sheep jetting, irrigation and more –

- Driven by a Honda GX160 or GX200 engine. The GX200 engine is also available in electric start.

- Patented clamped impeller design to enable longer impeller life and easier disassembly in case of blockage

- Single stage design provides the versatility of high flow rates with strong pressure

- Thrust balanced impeller design to extend engine life. Pump casing, diffusers and impellers manufactured from quality corrosion resistant marine grade aluminium for long life

- Choice of 3 or 4 way discharge port for easy installation with a choice of plumbing sizes

- Polyester coated pump casing, exterior and interior, for added corrosion resistance

- Patented floating impeller neckrings front and back help improve pumping efficiency and extend seal life, dramatically reducing engine wear

- Self priming from 7m for more versatile installation options

- Large priming and drain port with bayonet fit plugs to accept pressure gauges or drain cocks

- Low-oil protection on all models to protect your engine

- “HE” (electric start models) have electric starter and recoil starter fitted to ensure a choice of starting methods, even if the battery is flat or removed

- “HV” models come with Viton seal, o-rings, gaskets, caps etc. fitted for improved chemical resistance. (Please seek specialist advice from chemical supplier if pumping chemicals. Use of aggressive chemicals may void warranty.)

- All engines conform to the tough environmental requirements of the USA EPA and CARB standards, to help look after the environment

Rugged, economical twin stage engine driven pumps. Ideal for firefighting, tanker to tanker water transfer, high head general water transfer, sheep jetting, irrigation, boom spraying and more –

- Driven by either a Honda GX160 or a Honda GX200 engine which is specially designed for domestic or infrequent use. The GX200 engine is also available in electric start.

- Patented clamped impeller design to enable longer impeller life, improved performance and easier disassembly in the case of blockage.

- Twin impeller design provides extra strong pressure for longer and higher pumping applications.

- Thrust balanced impeller design to extend engine life.

- Pump casing, diffusers and impellers manufactured from quality corrosion resistant marine grade aluminium for long life.

- Polyester coated pump casing, exterior and interior, for added corrosion resistance.

- Patented floating impeller neckrings front and back. The front neckring helps improve pumping efficiency, the back neckring helps extend seal life and dramatically reduce engine wear.

- Self priming from 6m for more versatile installation options.

- Large priming and drain port with bayonet fit plugs. Plugs have safety retention system, plus are available with 1/4" tapping to accept pressure gauges or drain cocks.

- Low-oil protection on all models - engines won’t start or run if oil level is inadequate, thus protecting your engine.

- Electric start models have electric starter (battery and leads required) and recoil starter fitted, ensures a choice of starting methods, even if the battery is flat or removed.

- “HV” models come with Viton® seal, orings, gaskets, caps etc. fitted for improved chemical resistance. (Please seek specialist advice from chemical supplier if pumping chemicals. Use of aggressive chemicals may void warranty.)

- All engines conform to the tough environmental requirements of the USA EPA, CARB and the proposed Australian Emissions Standards, to help look after the environment.

Note: Only 5255H & 5265H are fitted with roll frames

- 1. Know the machine: Ensure all members of the household know how to locate and operate attachments like inlet and outlet hoses to the fire pump.

- 2. Fuel - Petrol: Petrol has a limited life and can become ‘stale’. Change the fuel every two months by running the pump or draining it of fuel. Better still, use a fuel stabiliser which will dramatically extend the life of the fuel (must be added when new fuel is purchased).

- 3. Fuel - Diesel: Has a longer shelf life but generally needs to be stored at low ambient temperatures. Expect diesel fuel to last 12 months or longer at an ambient temperature of 20°C, or six months at an ambient temperature of 30°C.

- 4. Engine oils: Engine manufacturers offer their own specially branded engine oils to best suit their engines. Synthetic multi-grade engine oil is NOT a suitable alternative. It is important to follow the manufacturer’s engine lubrication recommendations.

- 5. Run engine regularly to ensure oil is well distributed around the moving parts. This provides best lubrication and a longer working life.

- 6. Ensure your pump set has adequate clean air access: Check and replace the air cleaner or filter per engine manufacturer recommendations.

- 7. Keep the engine cool: Ideally protect the pump from radiant heat in a flame proof enclosure, otherwise add a mist spray around the pump or its enclosure to aid cooling and humidify the air.

- 8. General maintenance regime: Regular checks will ensure fuel lines are in good condition and the recoil starter works. A regular service schedule is invaluable.

- 9. Check the plumbing: Investigate and maintain the water system.

- 10. Check for leaves, debris and sticks that can impede the inlet system. For permanent installations, a foot valve and strainer at the end of the suction line can overcome obstructions.

- 11. Checked for air leaks and that all gaskets and seals are in good order.

- 12. An underground ring main installed around your property with durable hydrant or standpipe outlets can give you much greater coverage.

- 13. Practice: A well-rehearsed and documented fire plan is critical to personal survival.

So, as the summer fire season approaches the traditional motto of ‘be prepared’ applies. Establish your fire plan early. Adequately brief and train all family members in its resources and features.

Finally, ensure that all your fire protection equipment from a Davey Firefighter pump, to your hoses and nozzles are well maintained and able to operate without delay.

Depend on Davey.

For nearly 90 years, Davey has been manufacturing products that create perfect water pressure, healthy drinking water, protection from fire and flood, a clean, relaxing pool or spa, or water to run your farm or business, you can Depend on Davey for the right solution. A market leader in Australia, Davey also export to over 50 countries internationally where our products perform in some of the toughest environments.

Davey products are used in some of the world’s toughest conditions, which is why they are built with dependability and reliability at their core. Traditionally servicing the domestic water pumping, water treatment and swimming pool and spa markets, Davey has in recent years expanded its focus and product portfolio to include the commercial pumping, irrigation and commercial pool markets. As Australia’s leading brand, Davey are committed to keeping our communities safe and protected – especially those in who rely on our products, day in day out. You can Depend on Davey.

Talk to the team at Irrigear Lowood a member of Irrigear® Independent Experts to find out more about Davey Firefighter® Pumps as well as other water management solutions from Davey Water.

Irrigear®

Independent

Experts

GEARED

FOR BETTER

IRRIGATION®

Advice.

Products.

Solutions.

Australia-wide.

Enquiry form find out more

Share:

Irrigear Lowood